BUSINESS

Business Areas

ELECTRIC POWER EQUIPMENT

01

Polymer Housed Lightning

Arrester With Lead wire

Is a protection device installed in the processing distribution line to limit the overvoltage of the power system such

as lightning surge, switching surge and so on. It is manufactured using a ZnO-type Gapless device with excellent

non-linear V-I characteristics in a polymer housing with excellent weather resistance and electrical characteristics.

It is designed with a stable structure that prevents heat splashing and scattering caused by explosion of protective device.

In addition, the housing and lead wire are injection-molded to improve watertightness.

-

FEATURES

- If an abnormal voltage is applied, discharge to the ground to protect the power equipment

- Excellent response to surge by adopting ZnO type gapless element

- It is designed to discharge the internal pressure of the lightning arrester when it is subjected to thermal runaway due to fault, so it can be prevented from explosion and scattering.

- Compact and lightweight FRP structure with silicone rubber and filament winding, easy to handle and install, and no lead wire connection due to lead wire attached.

- Integral injection mold structure allows complete moisture shutoff inside

- Optimum structure for application in the field and excellent long-term longevity

-

TECHNICAL DATA

Rated Voltage 18 kV Lightning shock limit voltage 60 kV Below Nominal discharge current 5 kV Large Current Discharge Resistance 65 kA Continuous operation voltage 15.3 kV Lightning shock withstand voltage 78 kV Reference voltage(DC 1mA) 22.9 kV More than

02

Sheath Voltage Limiter

The sheath voltage limiter protects the cable layer, the GIS termination (EB-G) of the underground transmission cable,

and the insulator of the insulation joints. When a lightning surge or a switching surge is applied to a cable, a surge

is generated in the method layer and the cable shield layer to protect the insulation layer of the cable layer from being

destroyed. SVL was fabricated using a ZnO-type gapless device with excellent nonlinear V-I characteristics, and

was designed to have a safety structure that prevents explosion when the protective device is broken due to thermal

runaway.

-

FEATURES

- It is made of explosion-proof structure composed of FRP made by filament winding and does not affect other facilities due to failure.

- Since it is integrally molded with silicone rubber, it is waterproofed at the factory, and it is a perfect waterproof structure that does not penetrate moisture even when exposed to water for a long time.

- Only one side of the connection line is subjected to field conditions, so that it can be compressed and installed.

- Made of silicone rubber with self-extinguishing properties, it is a flame retardant structure with no risk of fire.

-

TECHNICAL DATA

1 Class(154kV) 2 Class(345kV) Rated Voltage 3.75 kV 5 kV Nominal discharge current 3 kV 4 kV Operating Voltage (DC) 2mA/4.2~6.4 kV 1mA/6.0~8.0 kV Protective Level : lightning impulse limiting voltage (10kA, 8/20㎲) up to 11.5 kVp up to 13 kVp Protective Level : fast-rising impulse starting voltage (10kA, 8/20㎲) up to 12.5 kVp up to 16.5 kVp Protective Level : switching impulse limiting voltage (500A, 30/60㎲)/th> up to 9.5 kVp up to 12.5 kVp Line discharge class/th> Energy absorption capacity over 10kJ Energy absorption capacity over 22kJ

03

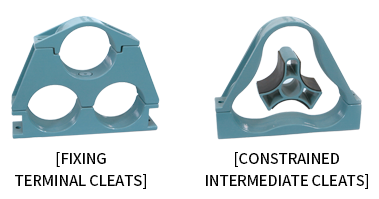

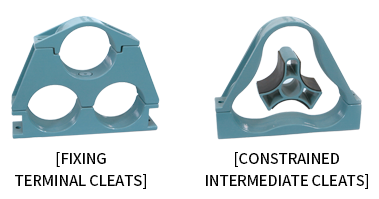

Cleat for phase Isolation

Install spacing brackets to allow spacers to be installed and spaced apart from each other during intervals where transmission capacity is insufficient. It is possible to maximize the transmission capacity without replacing the cable, thereby reducing costs such as replacement work and expansion of electric power.

Effect of application

- Increase ground transmission capacity by 8%.

- The construction cost is reduced by 3.2 billion won per km (345kV XLPE 2500mm2, phase isolation 50mm)

- It is possible to change the uniform installation method (Manpower-based installation -> mechanization installation method)

-

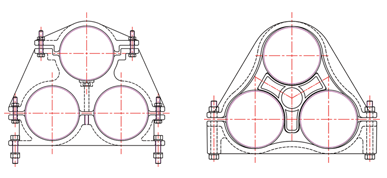

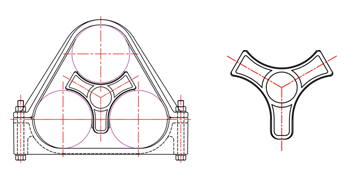

PRODUCT DRAWING

-

TECHNICAL DATA

Data Reference Main Body Material AC7A AC7A Tensile strength OVer 210 N/㎟ KS D6008 Elongation Over 12% KS D6008 Hardness Approx 50 KS D6008 Rubber plate Material CR rubber or equivalent performance Flame resistance Flammability (M3105 A method) KS M 3015 Hardness Over 52 HS KS M 6518 Tensile strength Over 14.7 N/㎟ KS M 6518 Elongation rate Over 350% KS M 6518

04

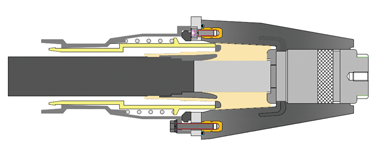

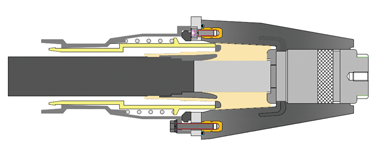

MV Plug-In CONNECTION

It can operate not only 25.8kV KEPCO underground power line but also 52kV ground voltage 26kV nominal current 1250A.

This is a connection material applied to MV power equipment such as GIS, CGIS, transformer, etc.

MV Plug-in connection is equipped with MV power equipment in advance and after completion of test delivery of the Test and Adapter Connector in the assembled state, It is a product that is easy to install and install because it has a structure that connects underground cable with plug connection material and inserts into socket after installation work.

-

STANDARD

Size 3 3-S Max. operation voltage Um (kV) 42 52 Rated voltage U (kV) 36 45 Line-to-earth-votage U。 (kV) 20.8 26 Nomianl current In (A) 1250 1250 Conductor RM RE RF RM RE RF Cross section(Guide value)2) Min.

Max.(㎟)

(㎟)35

80095

100025

40035

80095

100025

400Cross section(Guide value)2) Min.

Max.(㎜)

(㎜)15.5

46.046.0

55.015.5

46.046.0

55.0Votage tap With

WithoutWithout

(XL)With

WithoutWithout

(XL)Diameter of insulation3)

after removing the outer

semi-conducting layerMin.

Max.(㎜)

(㎜)6.1

36.010.5

36.06.5

26.86.1

36.010.5

36.06.5

26.8Rated AC voltage 5min. (kV) 95 117 Partial discharge level at 2 x U。 (kV) 200 ≤10 Rated lightning impulse

withstand voltage (BIL)(kV) 200 250 DC voltage test 15min. (kV) 125 156 Rated short time current 1s

3s(kA)

(kA)60

4060

40Rated impulse current (kA) 150 150

05

Epoxy Product

We have Automatic Pressure Gel Process (APG) facilities to manufacture

epoxy insulators for various power equipment up to 66kV class, and we

design, manufacture and supply according to customer's request.

We can select epoxy materials, product design and technical support

according to customer requested quality.

We also have complete manufacturing technology to provide epoxy

insulation products for high quality electric power equipment.

Our APG system has the technology to minimize the manufacturing process

defects by designing and manufacturing the equipment based on its long

experience, and it also has the mold designing technology optimized for

the equipment, so the epoxy for the power equipment up to 66kV Insulated

products provide competitive price and quality.

06

Metal fittings

All power devices are composed of insulating material that insulates the

conducting conductor from the conducting conductor. Among them, metal

fittings for connecting the conductors use various connecting methods

depending on the type and shape of the conductor.

As the resistance of the conductor metal is increased due to the electrical

and chemical corrosion caused by the use environment, the heat of the

connection part is increased and the electric equipment is frequently

damaged by the deterioration of the insulator by heat.

EPE can provide the design and manufacturing services of metal fittings

for conductor connection suitable for use environment of power equipment

to prevent electric equipment accident.

-

KINDS

- Shear bolt type conductor connection

- Cu-Cu conductor connection

- Al-Al conductor connection

- Cu-Al welding transition connection

- Multi-Contact type conductor connection

- Tulip contact type conductor connection

- Various metal fittings related to other power equipment

07

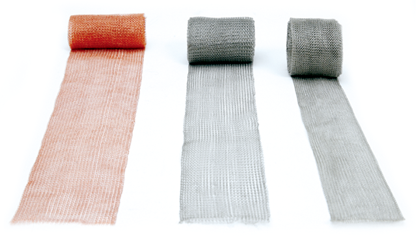

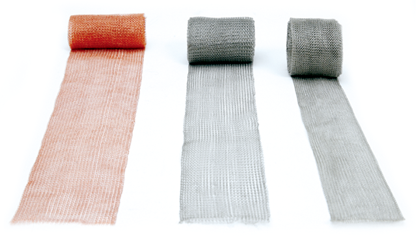

Copper wire mesh

Copper mesh tape supplied by EPE is used for the shielding of cable accessories.

It is knitted with annealed copper wire which is plated with tin. It is excellent

in conductivity and excellent in workAbility because it has excellent conductivity.

As an excellent material, it can be applied as a shielding material for various

power equipment.

Tin-plated copper mesh tape is excellent in soldering workAbility and provides excellent shielding effect when shielding parts exposed to corrosive environment or contact with sulfur-added rubber materials.

Tin-plated copper mesh tape is excellent in soldering workAbility and provides excellent shielding effect when shielding parts exposed to corrosive environment or contact with sulfur-added rubber materials.

08

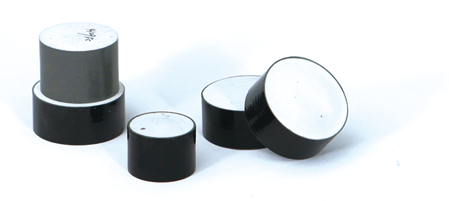

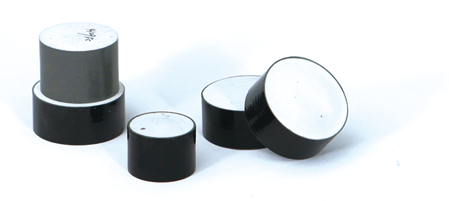

Arrester elements

Metal oxide varistors (MOV devices), which are sintered by mixing zinc oxide (ZnO)

and other metal oxide additives, have a ceramic layer with uniform zinc oxide

crystal size and high resistance to microvoids between crystal lattices.

It maintains insulation performance at normal voltage, but performs a lightning protection function in which an abnormal voltage acts as a conductor when applied. The devices fabricated in a perfect manufacturing process have excellent nonlinear V-I characteristics. Since quality inspection is carried out by conducting full inspection, uniform and perfect quality arresters can be manufactured.

Available product specifications are from Φ25 to Φ136, and it can be manufactured in series or parallel to make various DC, AC, distribution, and lightning arresters. EPE offers such metal oxide varistors (MOV devices) at competitive prices and excellent quality, and offers customized design, development and production services.

It maintains insulation performance at normal voltage, but performs a lightning protection function in which an abnormal voltage acts as a conductor when applied. The devices fabricated in a perfect manufacturing process have excellent nonlinear V-I characteristics. Since quality inspection is carried out by conducting full inspection, uniform and perfect quality arresters can be manufactured.

Available product specifications are from Φ25 to Φ136, and it can be manufactured in series or parallel to make various DC, AC, distribution, and lightning arresters. EPE offers such metal oxide varistors (MOV devices) at competitive prices and excellent quality, and offers customized design, development and production services.

-

CHARATERISTICS OF ZINC OXIDE MOV ELEMENTS

- Surge capacity is large.

- Fast response to the surge voltage and excellent protection characteristics.

- It is easy to shut off the fast flow because there is no fast flow.

- The voltage-current characteristic is symmetrical (DC-AC applicable).

- High reliability with high stability.

- Ceramic structure with low energy tolerance and high capacitance.